Keeping control of weight build up on any racing model is obviously vital. Tight construction leads to using less glue in joints, less epoxy in covering and less paint when finishing. I really wasn’t chasing every gram with the first build, the purpose of Fing2C 001 is to test fly, and then race if it proves suitable. I did learn that my building could be improved, become more accurate. And it also became apparent some areas were prime candidates for thinning down a bit.

The crutch & top deck was covered in glasscloth before the assembly commenced. I use my favourite Araldite standard to attach this to the wing. Then the carbon cooling duct was attached to the underside of the crutch followed by the U/C leg. After that the uncovered lower shell, which was only partially assembled. The front inboard quarter was the last section to be fitted. The only exception I make in using Araldite is to use JB weld for any areas subject to heating. JB weld has excellent capacity to withstand temperature, so the carbon Profi exhaust stub was glued to the duct using this method.

How strong is strong enough?

The racing life of an F2C model is harsh. Notwithstanding the vibration, taking off and flying forces, the real issues arise around the landing phase. The undercarriage can take a real beating from impacts, as does the whole airframe when the model is caught at the pitstop. Some pitmen have a softer catch than others, some pilots are easier on their models. The model is for racing, not caressing or polishing, so this is also a jouney to learn how robust is robust enough.

The trouble with making a model tougher is it usually adds weight, which inreases inertia, which inreases the loads exerted outlined above. These will find the weakest link and stress it, sometimes catastrophically.

How far to go with building in strength was a best guess. I’m sure a boffin time on their hands could do some finite element analysis and work it out. I’ll just go fly the thing (Fing) and see if it falls apart.

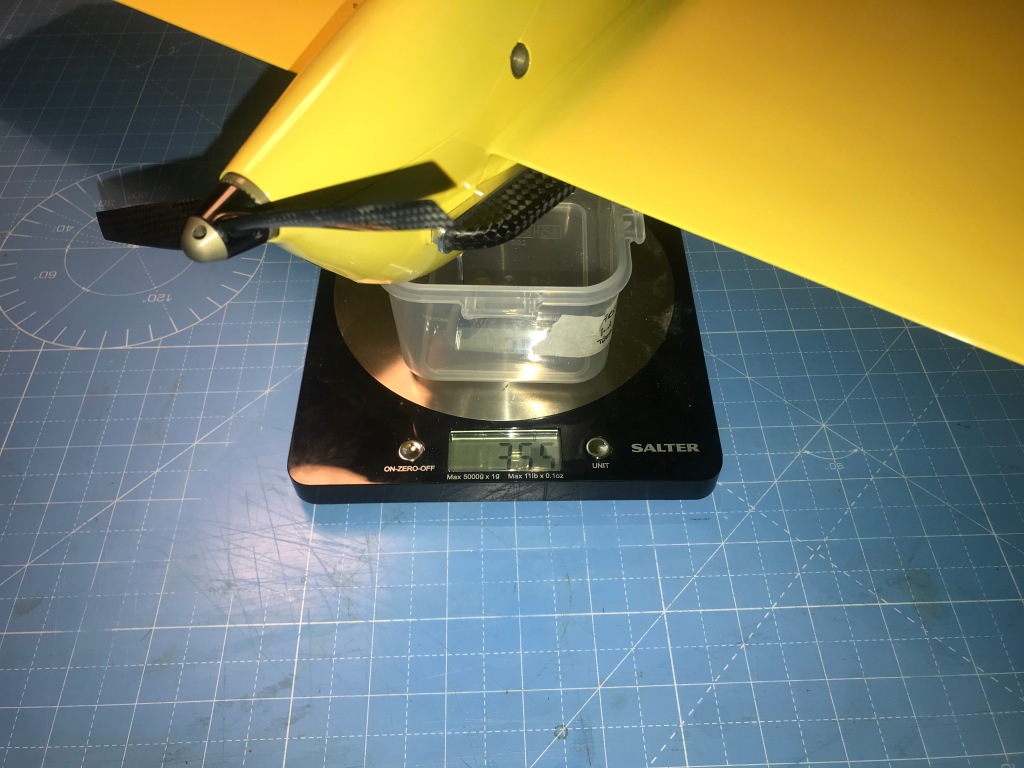

I aimed for an all up target weight of 350g. Engine c/w tank & airframe, complete and ready to go, as I figured this to be a realistic racing weight. The lightest models I have handled have been around 320g, but in some areas were fragile, and I’m sure if you dipped deep enough into your pockets lighter models are available.

But this is all about the real world, using easily available and cheap materials whilst trying to knock up something competitive with my bare hands.

Fing2C #001

It had to be yellow, my pitman prefers it……

Oops

You can’t expect to try new designs, ideas, building methods and techniques without the possibility of making an error. And I may have just muffed up royally. Or have I?

If you’d like to have a guess at what I may have overlooked, or have any other observation or feedback, I’d love to hear from you.

You must be logged in to post a comment.